Kalgoorlie Gold Mine Infrastructure Upgrade

KCGM’s Infrastructure Upgrade required high quality protective coatings to withstand the corrosive gold refining process.

The Kalgoorlie SuperPit

In late 2014, KCGM upgraded the gold processing infrastructure at the Kalgoorlie Gidji Roaster Plant. The upgrade included fabricated structural steelwork for various parts including pipe racks, tank lids, handrails and the cyclone structure. This was a particularly challenging assignment, well suited to the experience & professionalism of Ferro-Clean’s team. The specification was rigorous due to the highly corrosive chemicals used in the gold refining process, such as cyanide, lime and lead nitrate. Because these chemicals can significantly speed up the corrosion rate of steel and lead to structural failure much earlier than expected, the system required an Epoxy Zinc Phosphate primer with an Ultra-High-Build Epoxy Topcoat.

The key factor in choosing a protective coatings applicator was the need for high quality work to be done to a tight time frame – Rather than risk costly shut-down delays or repair work on site, the fabricator chose Ferro-Clean, to ensure work was done to schedule, passed third-party inspection, and gave KCGM (the end-client) assurance that their infrastructure would be protected from the harsh working environment.

What is the steelwork for?

Quality Inspection Equipment

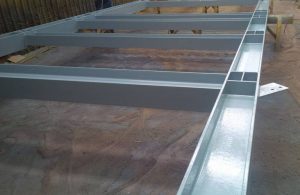

The steelwork package painted by Ferro-Clean consisted of the pipe racks, cyclone support structure and the leach tank roof; in the gold refining process, the ore from the Kalgoorlie ‘Superpit’ is taken to a series of mills, where it is crushed, and mixed into a slurry and pumped along the pipe racks to the cyclone (which separates the gold from the tailings. Chemicals are then added to further break down the ore and the slurry goes to the leaching tanks. The gold is then separated from the slurry by flotation and electrolysis and finally poured into gold bars for shipment.

How did Ferro-Clean help?

Pipe Racks during processing

Many fabricators would know that worrying about achieving deadlines and passing quality inspections can make a project very stressful. The fabricator for KCGM was assured in sending the complete package to Ferro-Clean, knowing that the same high standard of quality and attention to detail would be maintained, priorities would be listened to and the work would be completed consistently and efficiently.

Ferro-Clean has a customised componentry process and a designated handrail processing site to ensure that the smaller items in a job, which are often overlooked, are also completed on time and to specification. Ferro-Clean’s best practices have been refined to a level of excellence over the past 50 years, and we look forward to refining it further with your help, on your next project.