26 Oct Why Blasting and Surface Preparation are so important for Epoxy Paints on Structural Steel

Painting structural steel with epoxy coatings isn’t just about achieving a nice appearance; it’s a critical component in protecting and preserving the integrity of the steel itself. The key to a long-lasting and robust epoxy paint finish on structural steel lies in proper surface preparation. In this article, we’ll delve into the importance of blasting and surface preparation when using epoxy paints on structural steel, highlighting why the following steps are crucial for ensuring the longevity and performance of the coating:

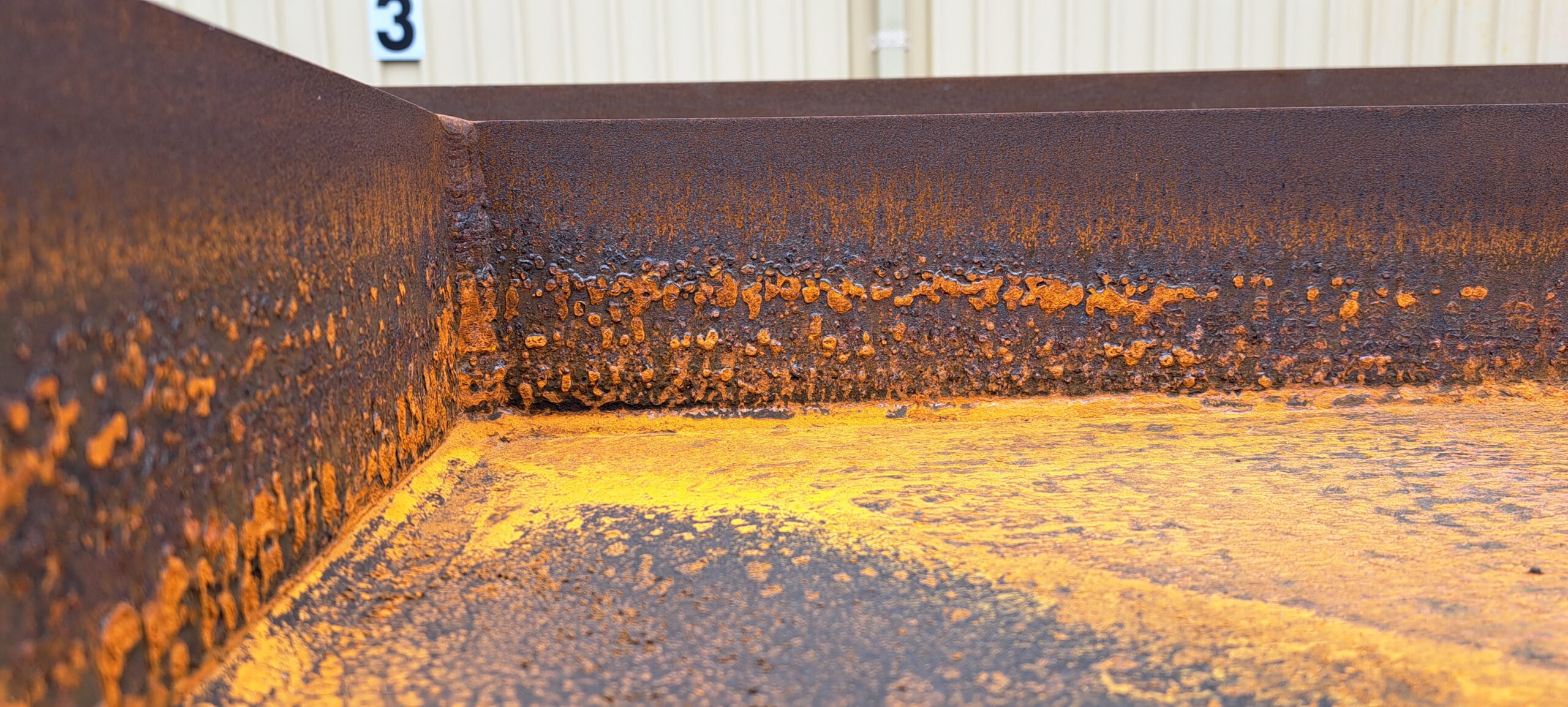

- Corrosion Prevention: Steel is susceptible to corrosion when exposed to environmental elements like moisture, oxygen, and contaminants. Proper surface preparation through abrasive blasting removes rust, mill scale, and contaminants, creating a clean and rust-free substrate. This is essential for preventing premature coating failure and extending the life of the steel structure.

- Adhesion: The adhesion of epoxy paints to the steel surface is directly influenced by the surface’s profile and cleanliness. Abrasive blasting creates a rough surface profile, allowing the epoxy coating to adhere tightly to the steel. Without proper adhesion, the epoxy may delaminate or blister, compromising the integrity of the paint system.

- Surface Profile: Achieving the correct surface profile is crucial for epoxy coating performance. Different types of epoxy coatings require specific surface profiles for optimal adhesion. Abrasive blasting allows for control over the profile’s depth and coarseness, ensuring it aligns with the epoxy’s requirements.

- Durability: Epoxy coatings are renowned for their durability and resistance to chemical exposure, abrasion, and UV radiation. However, for these qualities to shine, a clean and properly prepared surface is essential. Inadequate surface preparation can lead to the premature failure of the epoxy coating, resulting in costly maintenance and reapplication.

- Rust Prevention: By effectively removing existing rust and preventing its return, proper surface preparation is the first line of defence against the structural integrity of steel. Epoxy coatings act as a barrier, sealing out moisture and oxygen, but they can only succeed on a well-prepared surface.

- Contaminant Removal: Structural steel can accumulate various contaminants over time, such as oil, grease, and loose particles. Surface preparation removes these impurities, ensuring that the epoxy coating can adhere uniformly. Failure to remove contaminants can lead to uneven coverage and adhesion issues.

While the process of abrasive blasting and surface preparation may seem like an additional expense, it ultimately saves money in the long run. It extends the lifespan of the epoxy coating, reduces maintenance costs, and minimizes the risk of costly structural repairs due to corrosion and premature coating failure.

Proper blasting and surface preparation are the unsung heroes in the world of epoxy coatings for structural steel. These initial steps form the foundation for a robust, long-lasting, and high-performance coating system. Whether it’s protecting bridges, mining infrastructure, metal pipelines, or industrial buildings, the success of epoxy paint application on structural steel begins with these critical preparations.

Investing in the right surface preparation procedures ensures that your coating not only looks good but also serves its primary purpose – preserving and safeguarding the structural integrity of the steel for years to come.