With an automatic plate blasting machine and plate painting machine, Ferro-Clean is one of the best equipped protective coating applicators to process large quantities of steel plate in Perth. Ferro-Clean has been involved in plate jobs for petroleum tanks and the shipbuilding industry. Curved plate and straight plate can be processed, usually at the normal size of 2.4m wide by 12m long, up to a maximum size of 3.1m wide.

Having the flexibility to use pre-treated plates in large stock standard sheets for fabrication has distinct advantages. It means that plate work can be delivered to your workshop or site already properly blast cleaned and coated with a suitable holding primer. Edges can be protected during painting for non-weldable coatings, so the edges can be welded and coated on site.

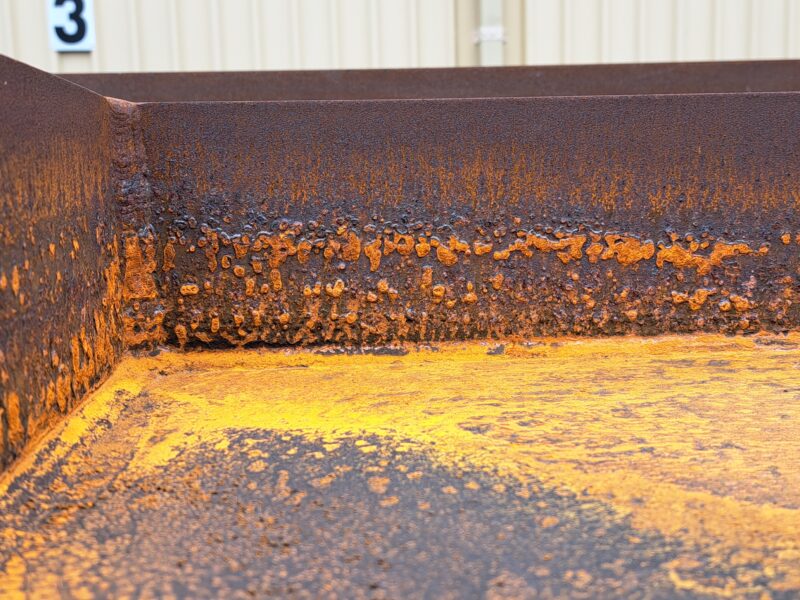

This allows the steel plate to be cut with ease, and can be welded through without affecting the integrity of the welding process. Painting in the workshop improves quality while reducing costly site work and potential safety hazards. Labelling and marking on plates can be done to your requirements by arrangement. Ferro Clean often paints impact plates with hard-wearing coatings to reduce wear & tear on flat steel surfaces. This is common on chutes and bins, where the coating can highlight areas that are badly worn, and therefore allow for maintenance before the plate wears through entirely, causing damage and loss of product.