Did you know that Australia’s structural steel fabrication capacity is around 1.8m Tonne, and of that, Western Australia accounts over one third, with a fabrication capacity of 640,000T. Driven by WA’s mining and construction boom, Perth has become a world-renowned manufacturing centre.

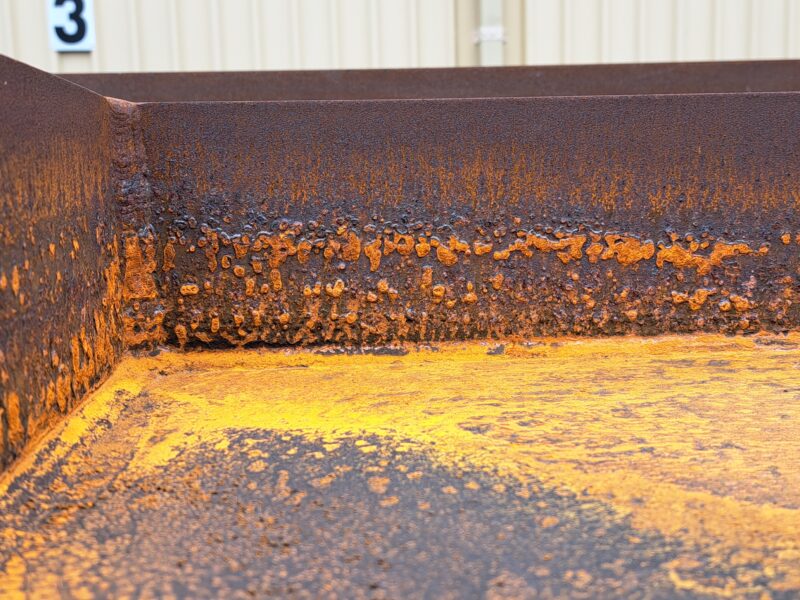

Obviously all this steel needs to be protected from the environment to extend its life and reduce the hazards that can result from corrosion. In 2006, annual corrosion costs in Australia were $28 billion and this figure is predicted to rise as mining enters the maintenance phase.

Ferro-Clean has multiple blast machines and blast rooms for surface preparation, and multiple large painting sheds. With a large team and the right equipment, your job will be in safe hands. Typically most structural steel paint jobs are a simple zinc coating or red-oxide or grey oxide paint, for internal steel for a warehouse or shed. If a particular colour is required, often a primer and top coat is applied, as most top coats can be tinted to any colour.

During the construction phase of a project, the emphasis is often on lowest price and fastest delivery. However, treating protective coatings lightly can cause multiple issues in the maintenance phase – site maintenance painting can be a costly and disruptive process, and requires extra safety and environmental measures to achieve the same result as properly applied workshop-based coatings at the beginning of the project.

Ferro-Clean is the partner of choice to get the job done, to specification and on time. We look forward to assisting your company to meet the needs of your clients – protecting their assets well into the future.